Installations

UK Rigging operates a full design, installation and fabrication department and has carried out a wide variety of installation work.

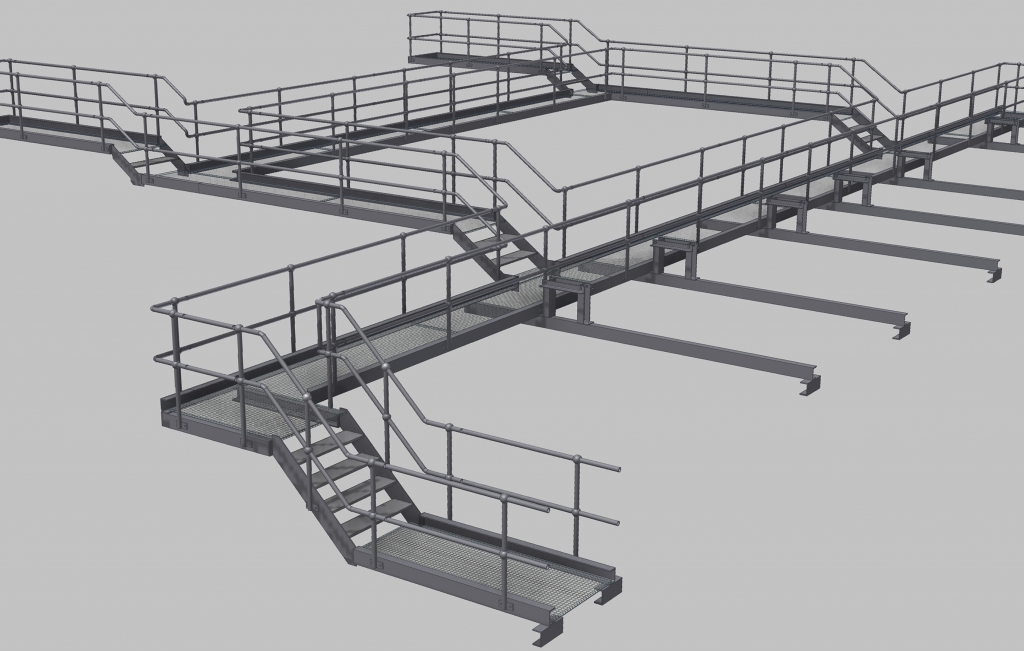

Design

UK Rigging initially carry out a site survey to establish what is required, scale, material requirements, problems that may be encountered, deadlines and costs.

UK Rigging use AutoCAD and Autodesk inventor to design projects and FEA (Finite Element Analysis) to ensure structural integrity. Three dimensional visuals are produced, enabling the client to view what the finished product will look like.

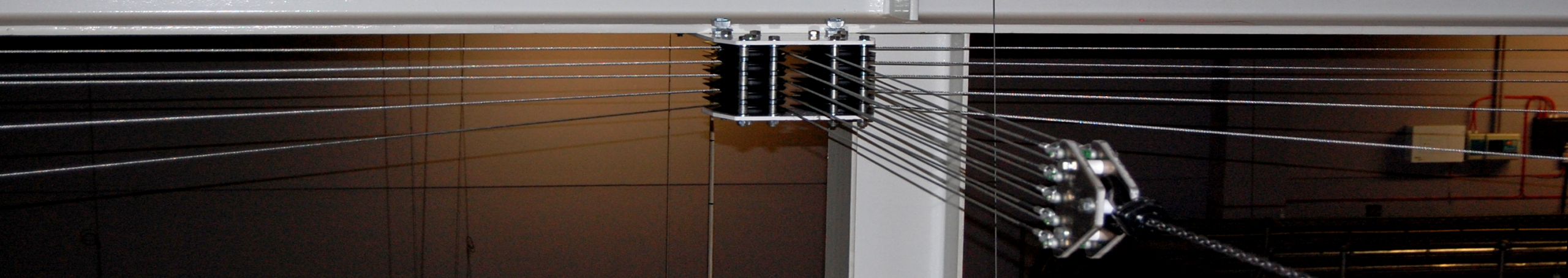

Fabrication

Our in-house fabrication team use the latest technology to ensure products are fabricated accurately and exactly to plan.

Installation

The project manager along with an experienced team of rigging installation engineers carry out the installation. The same principle is applied to installations as is it to all of our rigging work, we use carefully selected competent staff who are suited to the task, we work to strict deadlines, adapt to the clients schedule and fit installation work around scheduled events so not to disrupt any usual activities of the venue.

A specific health and safety file is produced for every installation. This includes the full health and safety policy, a method statement which details how the installation will be carried out, a specific risk assessment, rescue plan and relevant insurance documentation.

Every installation comes complete with instructions where necessary, outlining how the product should be used, any maintenance that should be carried out and how often the product should be tested and inspected.

Maintenance

When required, UK Rigging manage the installation for the lifetime of the product, carrying out the necessary maintenance and inspections according to the relevant regulations for the particular product. This can be arranged as required or as an agreed maintenance schedule.